“Science may have found a cure for most evils; but it has no remedy for the worst of them all – the apathy of human beings” – Helen Keller

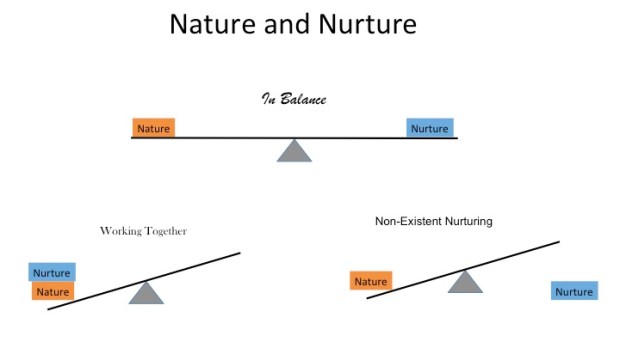

Nature + Nurture = Outcome

Positive + Non-Existent = Apathetic Safety

Continuing on the theme of nature versus nurture, what happens when someone has a positive safety behavior and enters an organization that is neither positive or negative? The company has no safety culture at all. There is lasissez-faire attitude toward the safety culture of the site.

Nature versus nurture is a complex process of what someone is born with and what they are exposed to. There is significant debate as to the amount each contributes to the whole of a person. When this process is look at from a person and organizational stand point, there are opportunities to better understand how these processes interplay for safety. When various internal behaviors (nurture) are encountered with various organizational cultures (nurture), there are varieties of ways the sum of the parts create an outcome.

When there is a positive nature and a non-existent nurture, it creates a neutral safety organization. In other words and individual has the desire to work safe and the organizational culture does not care either way. So what would this non-existent culture look like:

– There is basic regulatory training. It is conducted in the most efficient manner

– There are not shift discussions on safety

– Safety is only important when there is an incident, usually an injury

– There is no proactive process to measure safety

– The key measurement is LTIR and TCIR.

The company does care about safety, but from a high level it is based on keeping insurance rates low and preventing regulatory interference. What is means is that there is risk for the employees and there is no external motivation to create systems to make it better. Safety is up to the individual.

Each day the personal will make a choice. They are not discouraged from making the right choice such as setting up a lockout-tagout or confined space entry process. There is also no discouragement from not performing them either. This creates a significant false sense of security.

As an individual they are making internal choices based on their own process for evaluating risk. Some are much more willing to take risk than others. This can create an illusion that everything is fine with the safety programs and processes. From a legal standpoint, they are able to show training and written programs. A walk of the process may show some opportunity, but not blatant mishandling of safety processes.

What this has created is apathy. There is not desire to get better. There is no influence to make it worse. In a negative culture, it can create a kind of backlash where people are working to get more attention on their issues. They are focused on the items that make the environment unsafe. They may be focused on trying to create some change. The neutrality of the safety program is one that is creating the idea that things are okay, so why worry to much about making improvement.

Apathy in safety is a scary idea. When a company believes that it is “good enough” when it comes to safety and it stops focusing on continuous improvement, there is a huge opportunity for risk. The Chemical Safety Board has many examples of good companies that felt they had gotten their safety program to where it should be and stopped pushing to make it better. The apathy created the opportunity for major disasters.

To combat apathy as part of a safety culture, there has to be a focus on continuous improvement. There needs to be a feedback loop so that the program can be evaluated and those that are served by that program have the opportunity to give input to the improvement cycle. There needs to be proactive metrics that are not only collected but are part of a system that helps to drive positive cultural engagement and change. When it comes to safety culture, apathy is dangerous.